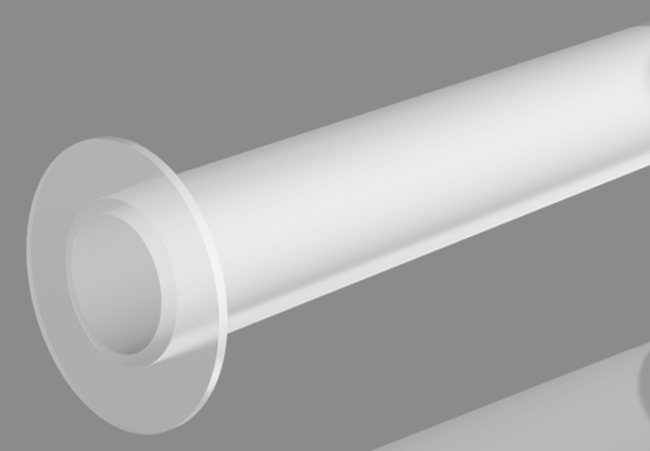

The materials used for each component of complex medical devices are crucial to therapeutic efficacy and patient safety. Fluids, gases, and microscopic tools are carried by tubing in anything from minimally invasive surgical devices to complex diagnostic equipment. These ptfe medical tubing must be biocompatible, sturdy, and exact and often accept harsh environments. Polytetrafluoroethylene medical tubing has set a gold standard for performance and improved patient safety and comfort.

The Rigorous Demands on Medical Tubing

Medical tubing works in extreme conditions. It must interact with body fluids, tissues, and delicate drugs inside without harming or degrading them. Externally, it must survive sterilization, repetitive handling, and complex gadget motions. Leaching of dangerous chemicals, material deterioration, or kinking in tubing can affect patient health and medical operations. A material with a unique balance of attributes is needed to provide consistent, safe, and effective performance. Traditional materials generally fail to meet these needs.

The Unrivaled Properties of PTFE

Synthetic fluoropolymer PTFE has special qualities that make it ideal for medicinal applications. As a biocompatible material, PTFE is practically inert and non-reactive with biological systems, reducing the possibility of simple immunological reactions or material toxicity. Critical drugs cannot be fascinated or adsorbed due to their lifelessness, guaranteeing proper drug administration. PTFE has a very low coefficient of friction, making its surface smooth and non-stick. This property reduces friction when tubes pass through sensitive vasculature or prevents biological material faithfulness. PTFE is also chemically resistant to many medical cleaners and corrosives and thermally stable, allowing it to tolerate high-temperature sterilization without deterioration.

Enhancing Patient Safety and Clinical Performance

Excellent characteristics of PTFE enhance clinical performance and patient safety. The non-stick surface of ptfe medical tubing lowers blood clotting and protein deposition in urological and cardiovascular applications, therefore lowering blockages and difficulties. Its great lubricity simplifies catheter and guidewire insertion and navigation over complex anatomical routes, therefore reducing patient discomfort and tissue damage. PTFE’s chemical inertness prevents hazardous compounds from entering the patient’s system, preserving medicine purity and preventing deadly responses. Devices help infection control methods by remaining sterile and functioning after several sterilization cycles.

PTFE in endoscopic and laparoscopic tools insulates and smooths instrument and fluid flow. It is also used in medication delivery systems, analytical equipment, and medical device cable covering. Because of its biocompatibility, lubricity, chemical inflexibility, and thermal stability, PTFE tubing is the gold standard in manufacturing of medical devices. Its key characteristics enhance patient safety by lowering adverse reactions and complications and by guaranteeing device functionality, therefore smoothing operations and clinical performance. PTFE tubing will only grow more crucial as medical technology develops if we are to guarantee the finest patient results anywhere.